The cooling fans reliability of their bearings is very important, and the type of bearing used by the fan is also very important. So how to choose the cooling fan bearing system?

The best fan bearing system for cooling fans is double ball bearing. The advantages and disadvantages of sleeve bearing, ball bearing in fan bearing system as follows:

Advantages of using sleeve bearing

1. Resistant to impact of external forces, less damage caused during transportation.

2. The price is cheap, compared with ball bearings, the price difference is great.

Disadvantages of sleeve bearing

1. Dust in the air will be sucked into the core of the motor due to the operation of the fan motor, which will mix with the lubricating oil stored around the bearing to make the operation noise, or even get stuck.

2. Bearing inner diameter is easy to wear, short service life.

3. Can not be used in portable products.

4. The clearance between bearing and shaft core is small, and the operation and activation effect of motor is poor.

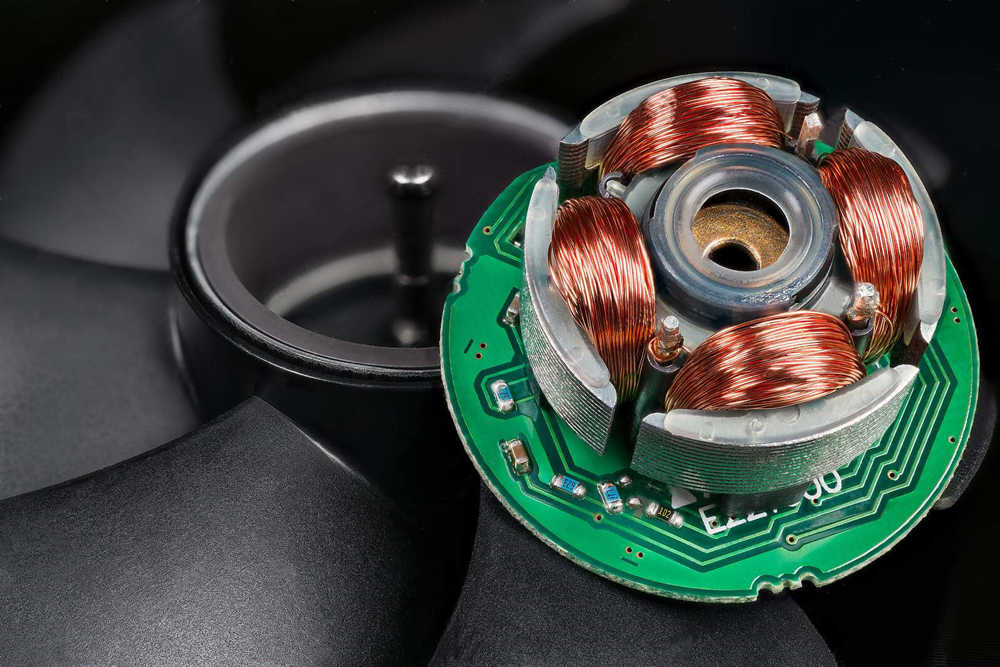

Advantages of using ball bearing

1. Metal bead operation belongs to point contact, so it is easy to activate the operation.

2. Rolling to generate friction, so the contact surface is small and the coefficient of friction is also small.

3. It can be used in portable products which are often operated in different angles and directions.

4. Compared with sleeve bearing, the service life is longer.

5. Ball bearing system features high efficiency and low heat generation.

Disadvantages of ball bearing

1. Bearing structure is quite fragile, unable to withstand the impact of external forces.

2. When the motor is rotating, the rolling of the metal bead will produce a large noise.

3. The process is more complex and the price is high, so it can not compete with the oil bearing in the cost price.

4. Ball bearings use the elasticity of spring to position them, and it is not easy to assemble them.

Ball bearings are used for high speed fans and sleeve bearings are used for low speed fans. More advanced than single ball is double ball bearing. Sleeve bearing life is generally 10,000 hours, single ball bearing is 30,000 hours, double ball bearing is more than 50,000 hours.

The ball bearing replaces the sliding friction by rolling friction. The friction coefficient is small and overcomes the disadvantage that the friction coefficient is easily changed. Therefore, the running stability is strong and the service life is relatively long.

So choose the cooling ball bearing system to choose double ball bearings. It has advantages over other bearings in use.